FINAL PROJECT

WEARABOX: PRESENTATION

WEARABOX: MAKING OF VIDEO

FINAL PROJECT FIRST STAGE: COLLECTIBLE PACKAGING

Abstract from: Packaging waste from food delivery in China’s mega cities. Guanghan Songa, Hui Zhanga, Huabo Duana, Ming Xu.

Door-to-door fast food delivery service has become increasingly popular in cities due to the fast development of e-commerce and the fast-paced life in China. This in turn has resulted in significant environmental concerns for the waste packaging materials. We have therefore estimated and predicted the volume and composition of food delivery packaging waste in China. The results show that the total amount of packaging waste surged from 0.2 million metric tons in 2015 to 1.5 million metric tons in 2017. Accordingly, we have provided several policy suggestions to tackle this pressing issues, particularly using the Reduce, Reuse and Recycle environmental friendly practices.

PROBLEM

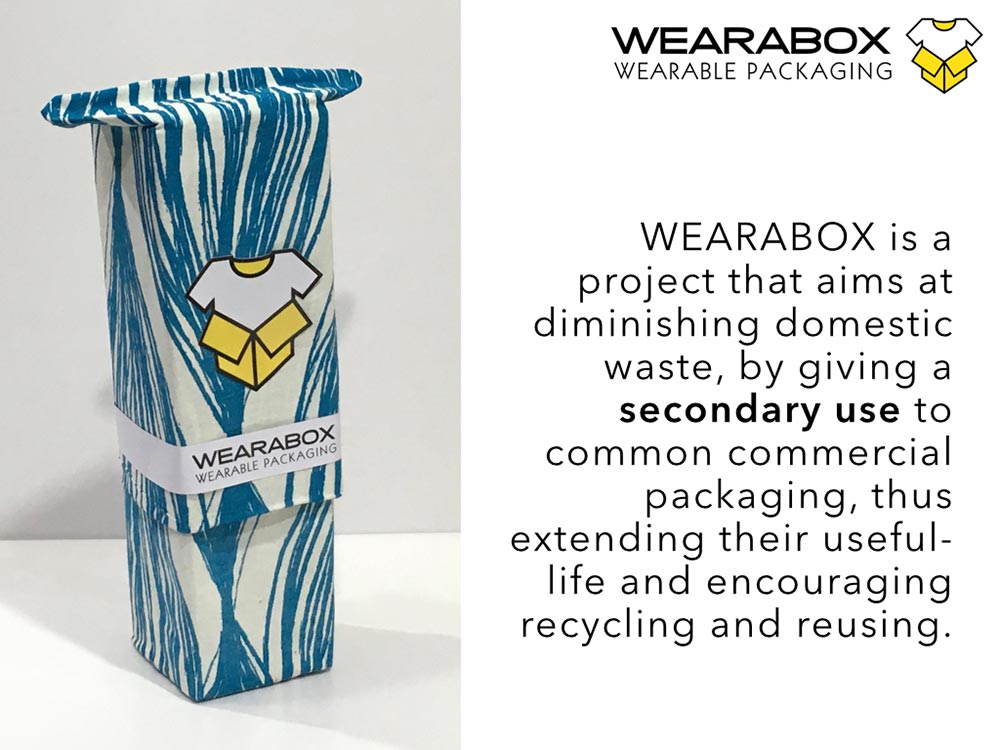

China is facing a BOOM in home delivery, boosted by e-commerce and low prices. The result is an incredible amount of packaging material being used everyday and going to waste as soon as it has completed its very short life cycle. What if packaging had a second use, therefore a second life? My final project moves tries to address the problem by making the packaging material something desirable, because it has a new use after the foirst one. Something that people might want to keep and that has as much value as what was contained in it.

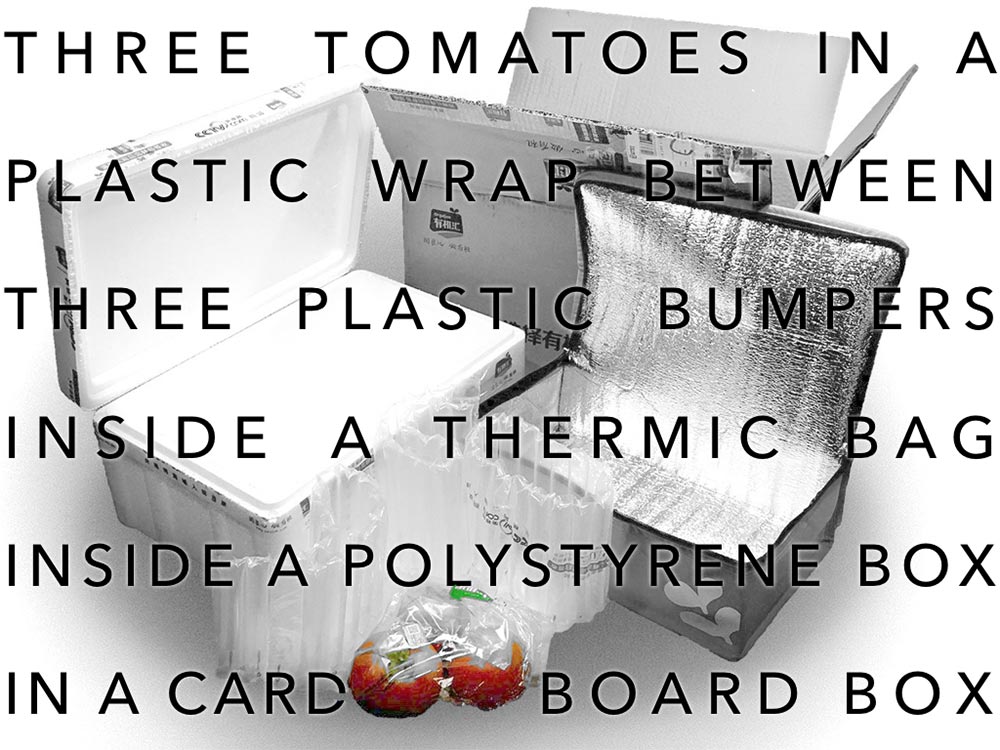

The photo on the right was taken by me at a friend's house, it shows the packaging used to delivery THREE organic tomatoes: a cardboard box, a polystyrene box, a thermic bag, three air bumpers and a plastic wrap. Also, the tomatoes didn't taste good.

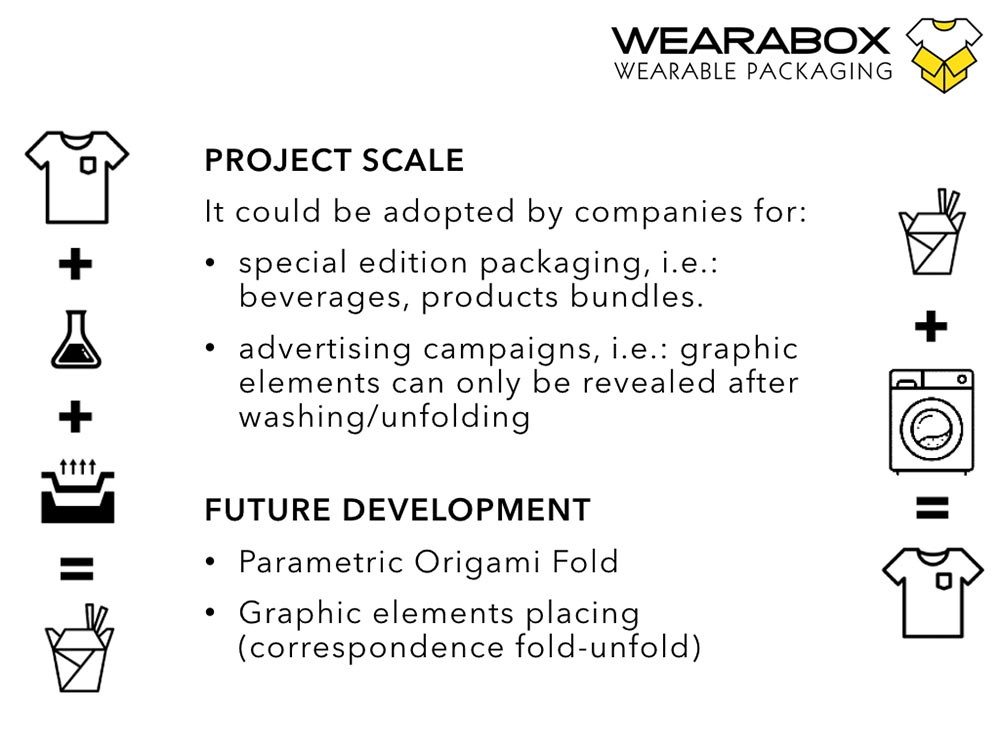

Collectible packaging

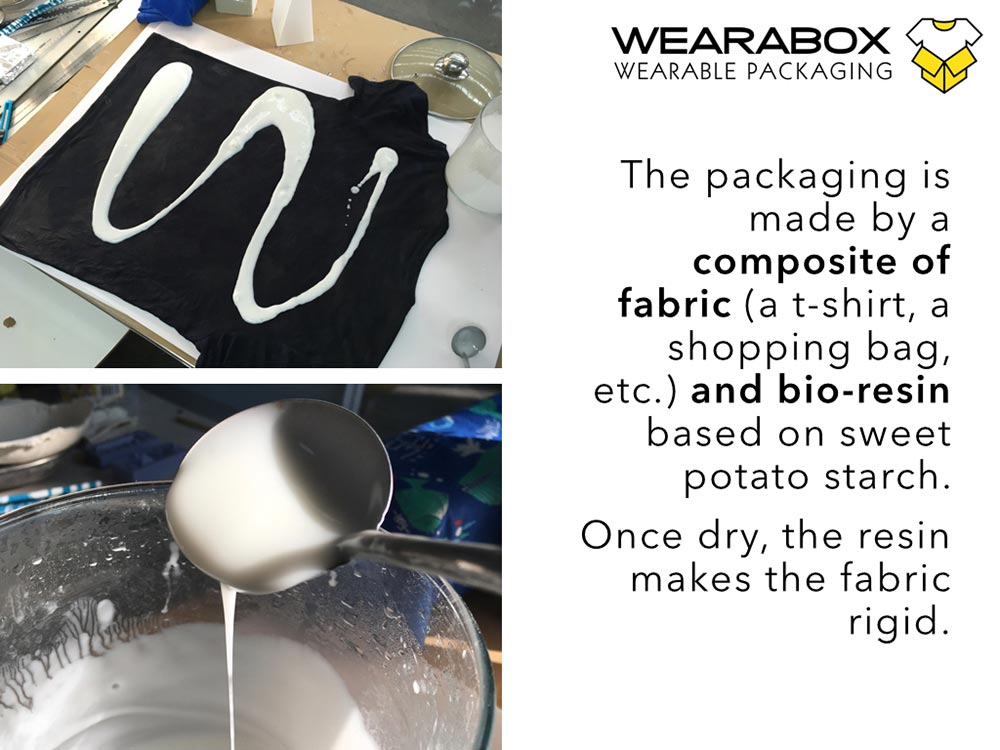

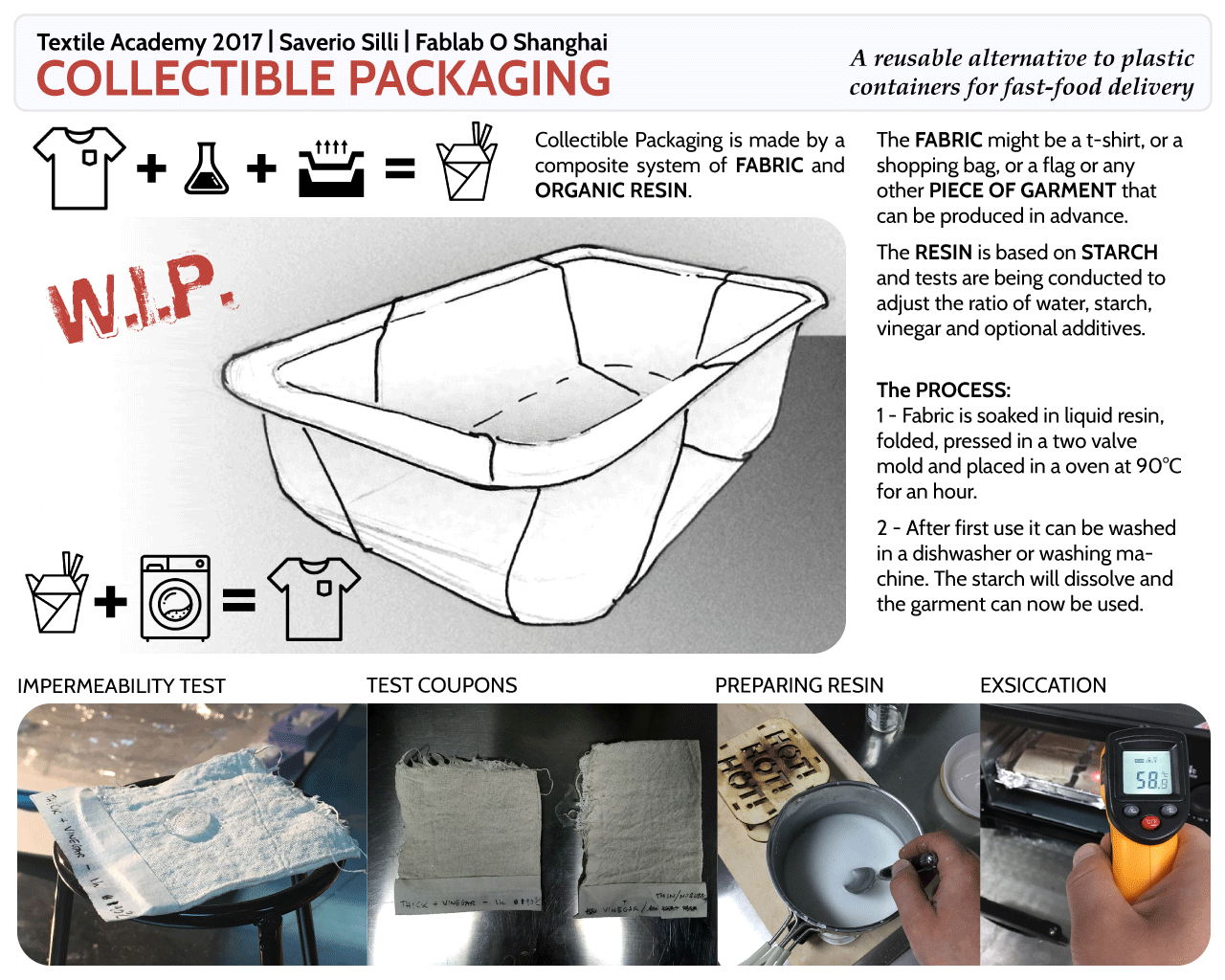

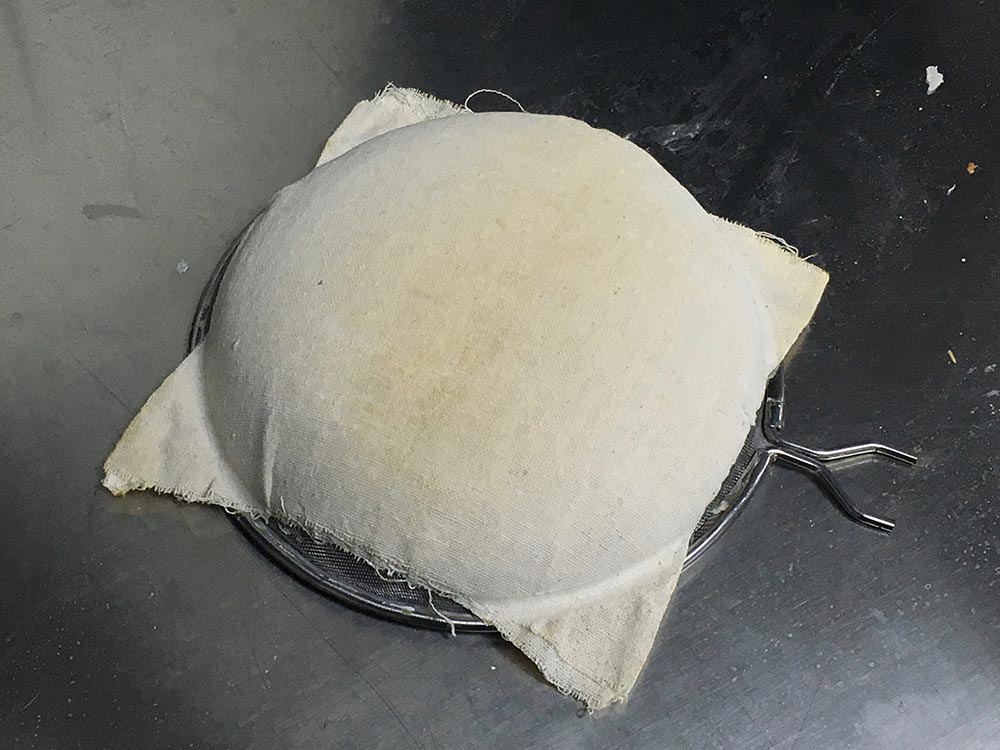

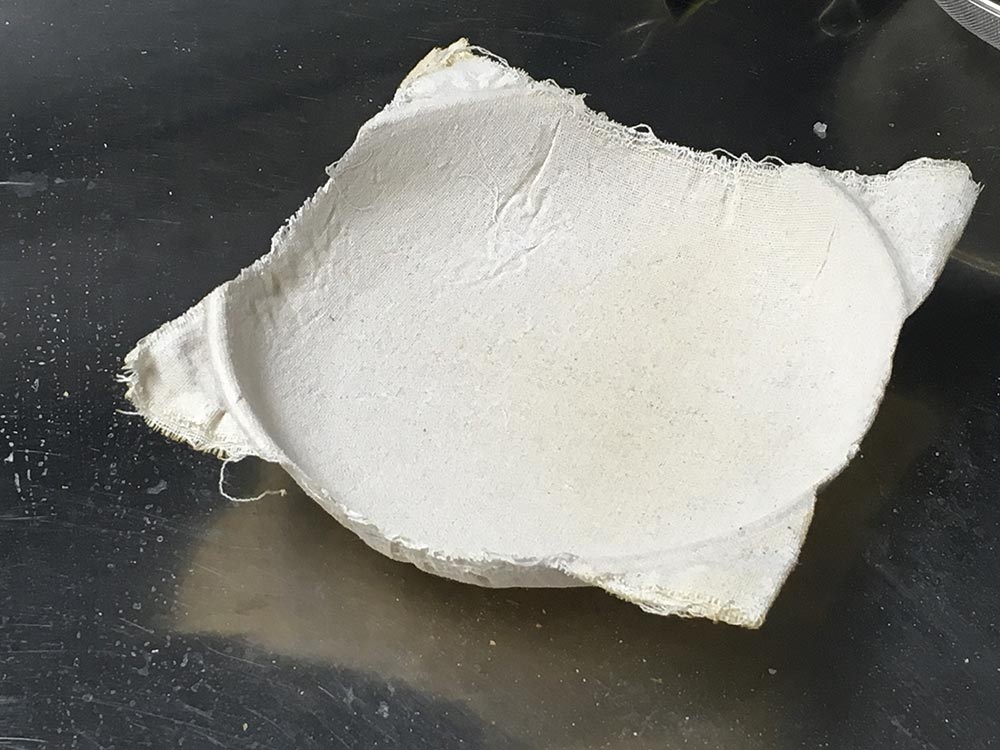

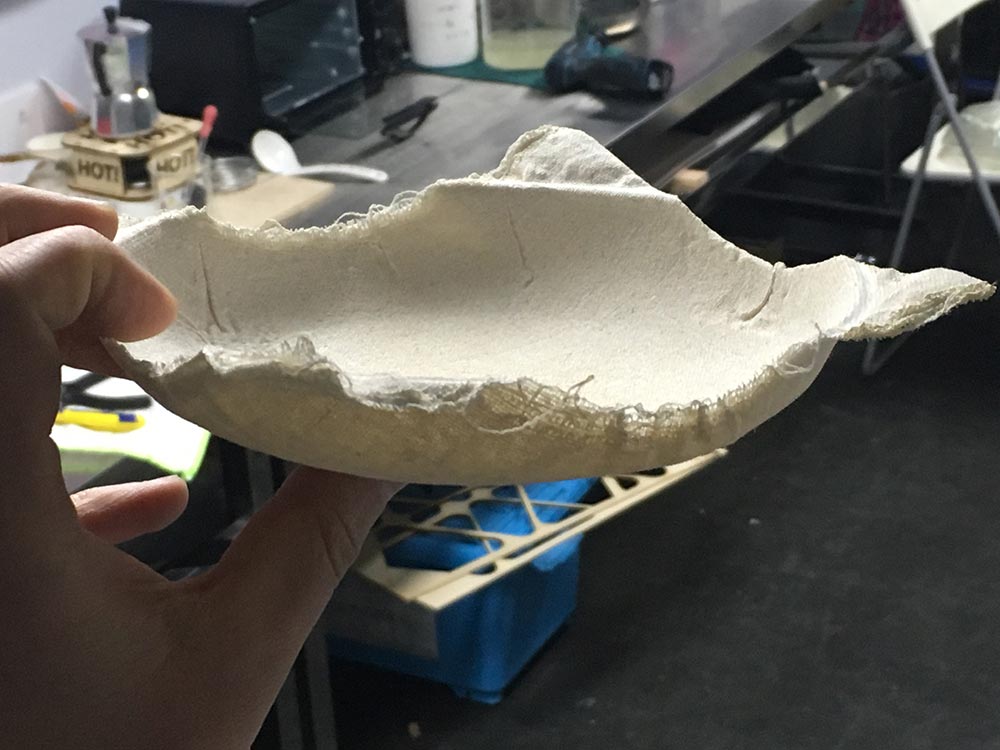

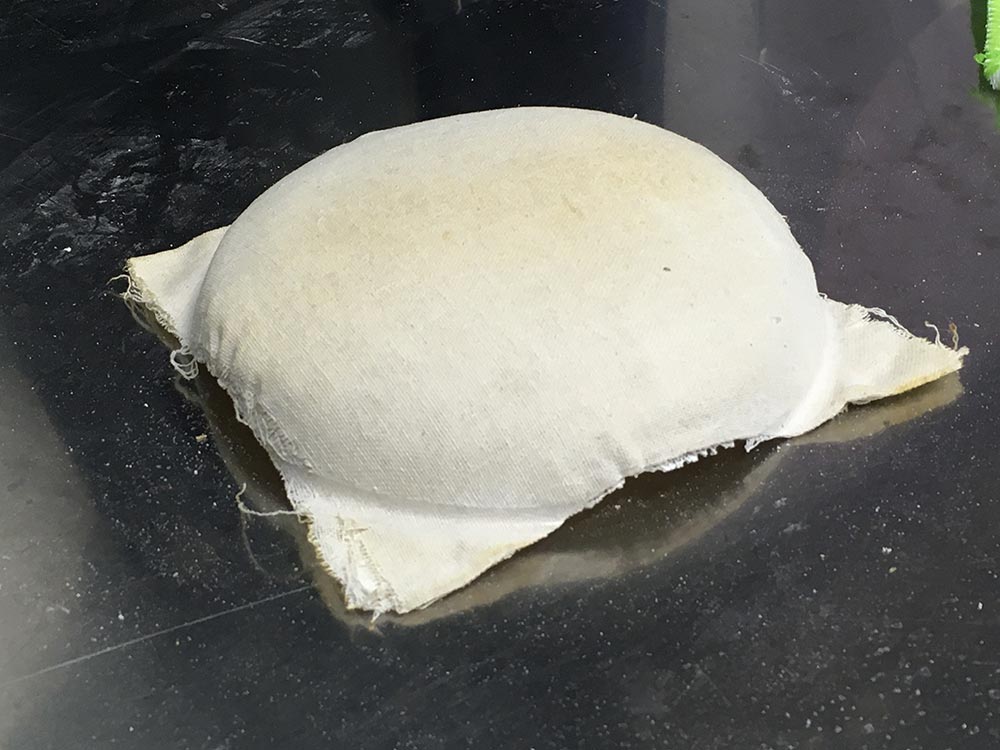

Collectible Packaging is a reusable alternative to plastic containers for fast-food delivery or other type of deliveries. It is made by a composite system of FABRIC and ORGANIC RESIN. The FABRIC might be a t-shirt, or a shopping bag, or a flag or any other PIECE OF GARMENT that can be produced in advance. The RESIN is based on STARCH and tests have been conducted to adjust the ratio of water and starch and additives like vinegar.

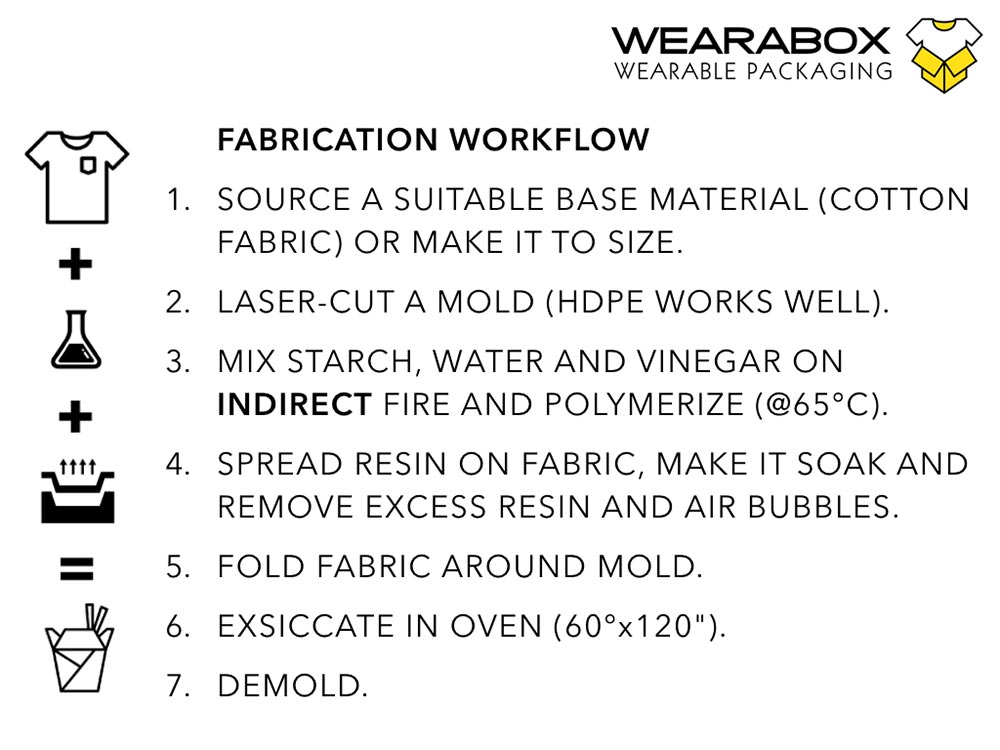

The PROCESS:

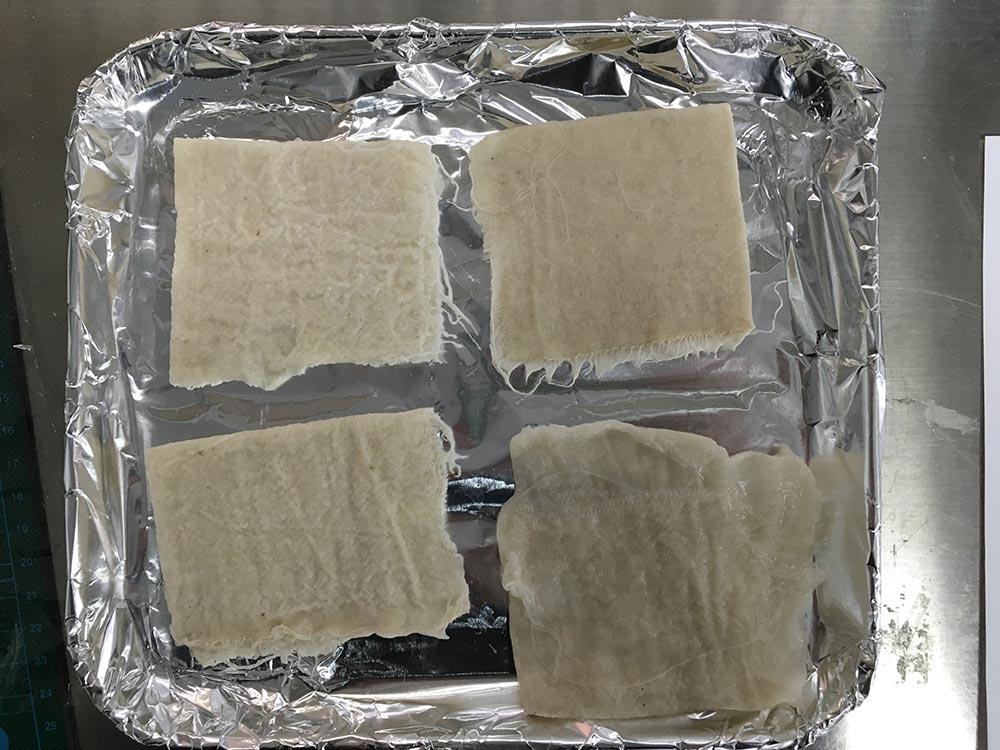

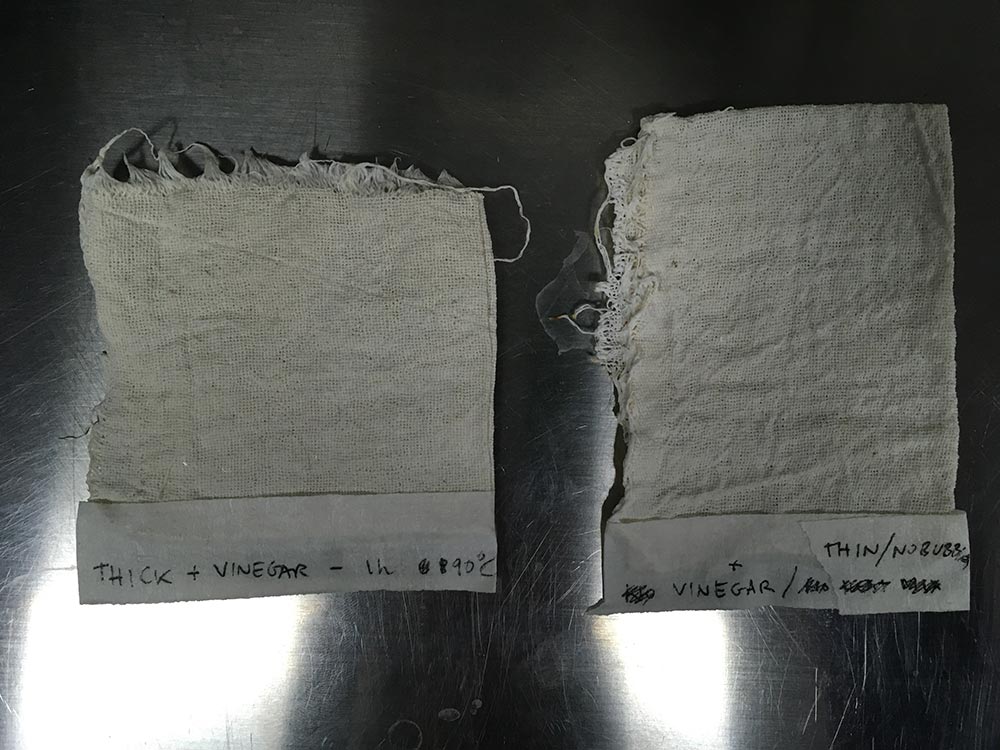

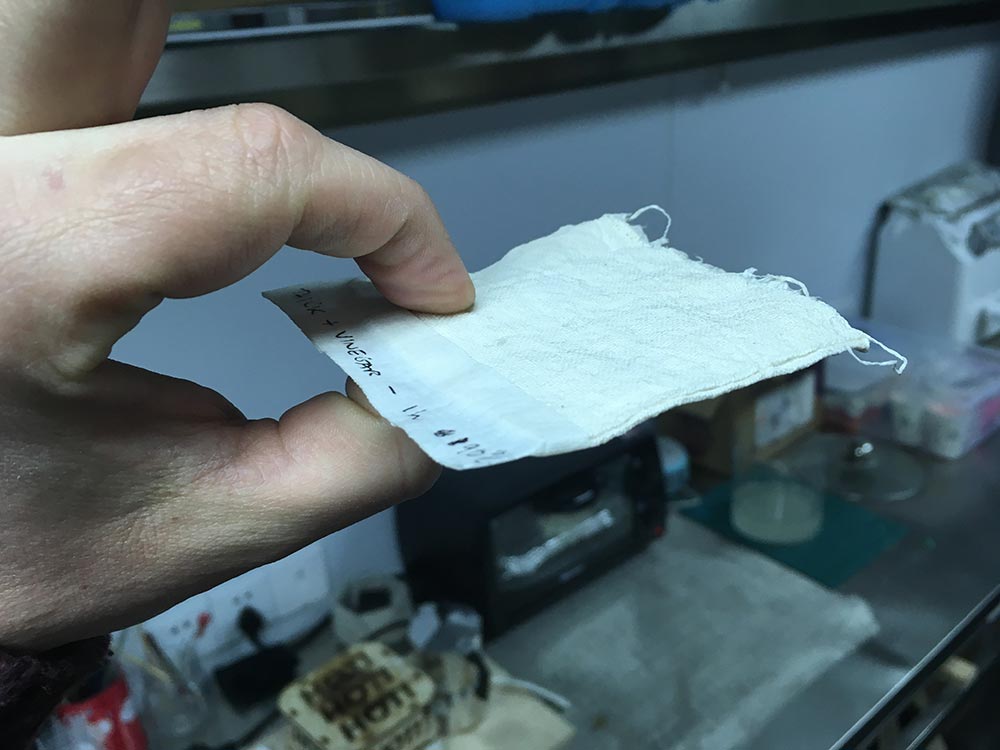

Testing the composite material

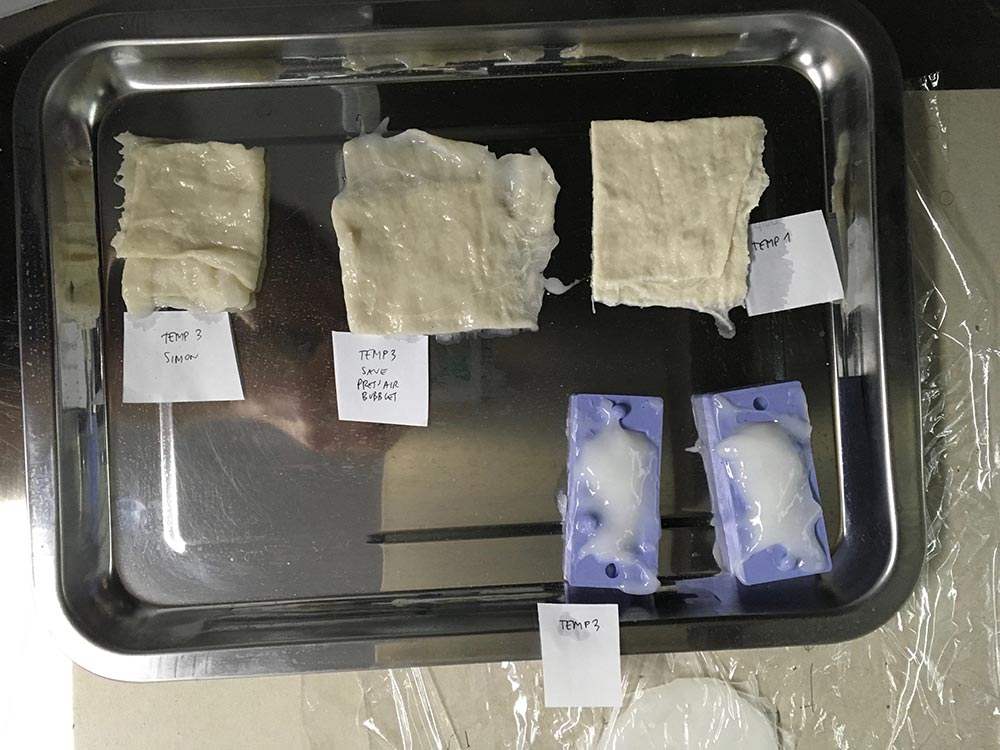

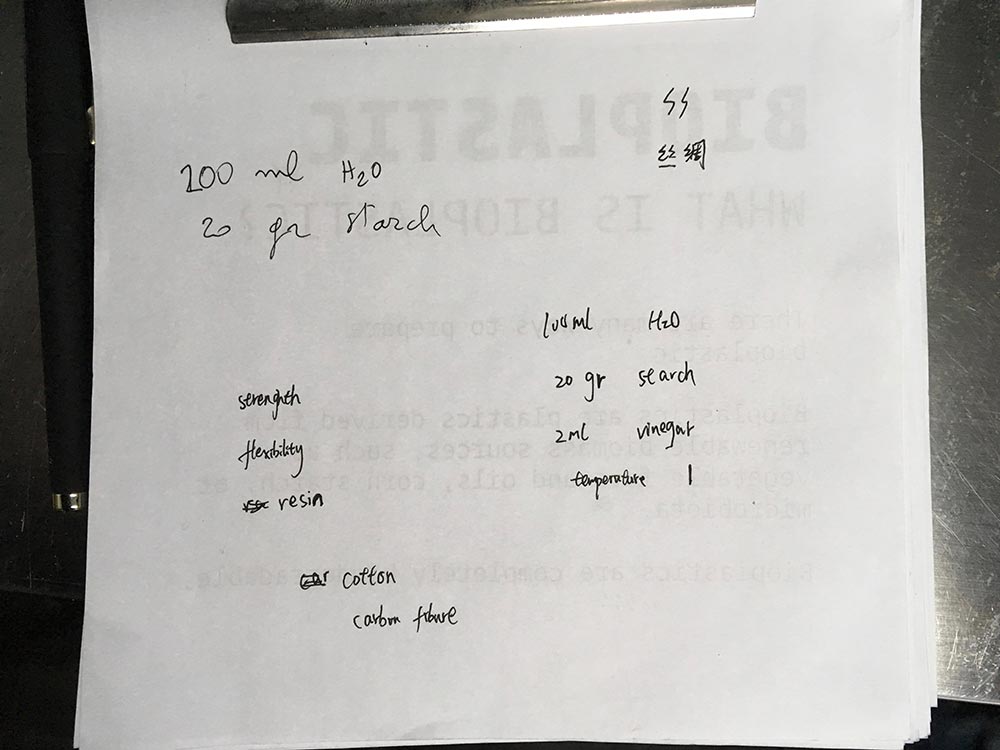

The composite material I use for my reusable packaging is a mix of cotton cloth and sweet potato starch. I made many tests, changing amount of the two components, adding vinegar, varying the cooking and essication temperatures and times. The final formula is:

The material resulting from this formula is very strong yet flexible (the vinegar helps the starch polymerize and make it elastic). It has a good water resistance (a drop placed on a test piece remained unabsorbed for more than 3 hours, and the same result came with simple submersion) and it is lightweight. The vinegar must be carefully measured, too much makes the material too resistant and it makes it difficult for the starch to dissolve when placed in the washing machine for reuse.

Simon helped me conducting the tests

This website by Saverio Silli (based on Twitter Bootstrap) and all its content is licensed under the following license: CC Attribution-Share Alike 4.0 International.