The Textile Scaffold

Class seven - 7 November 2017

Experimenting with Colophonia and various materials

I have experience with polyester resin and other kind of chemical compounds used to make composite structures but I wanted to explore something more environmental friendly. Surfing the net I discovered that Colophonia is produced 90% in China from trees resin. I acquired a bag of colophonia crystals, also known as rosin, violin rosin or flux: it is the basic components of soldering flux paste and it is used on stringed instruments to make the horse hairs on the arc transmit the fibration to the strings.

I often rely to an italian website called Antichità Belsito to get documentations on materials used for molding & casting, composites and generally anything used for old fornitures restoration as it sells all the materials used in the long tradition of furniture making. Colophonia, aka Pece Greca (Greek Pitch) is one of those. They say it can be diluted with alchool or other paint thinner.

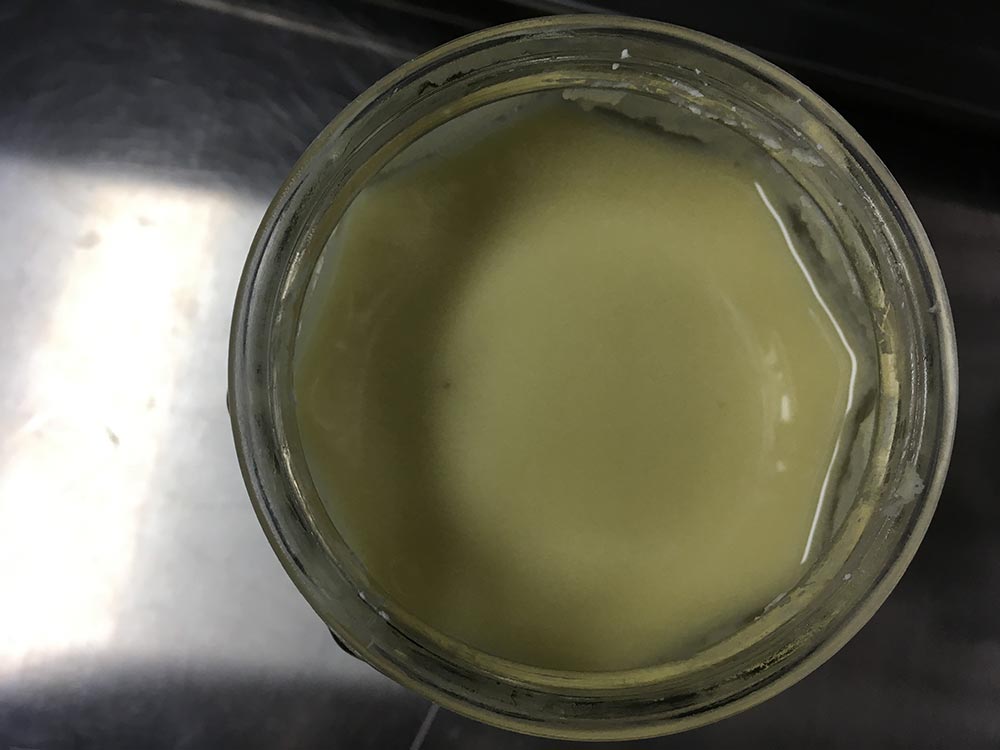

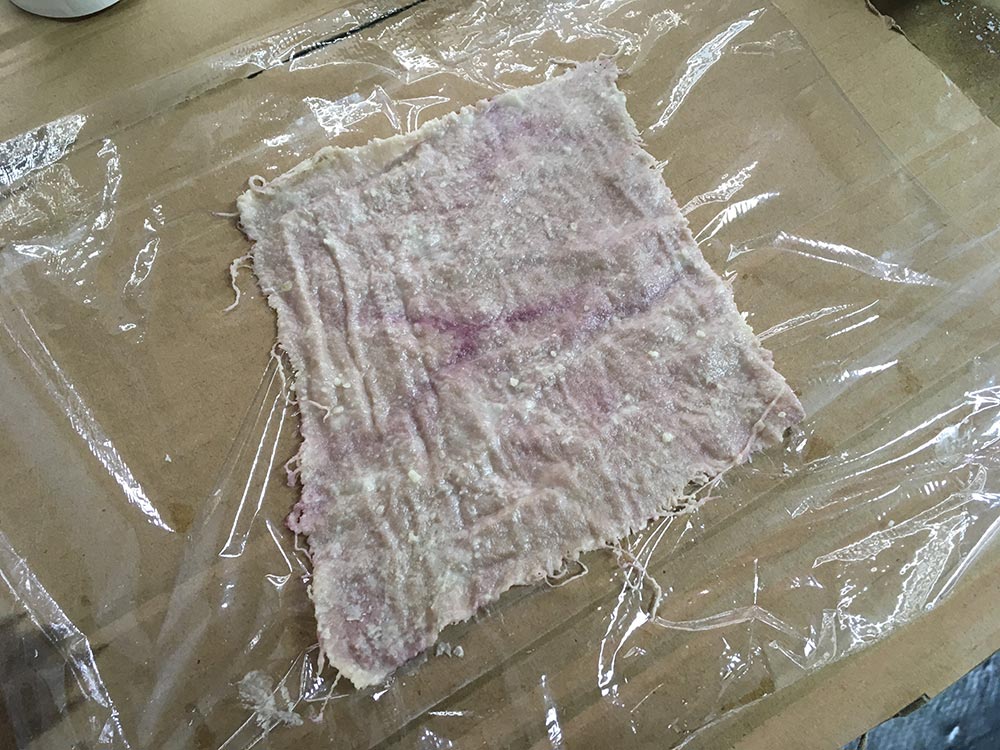

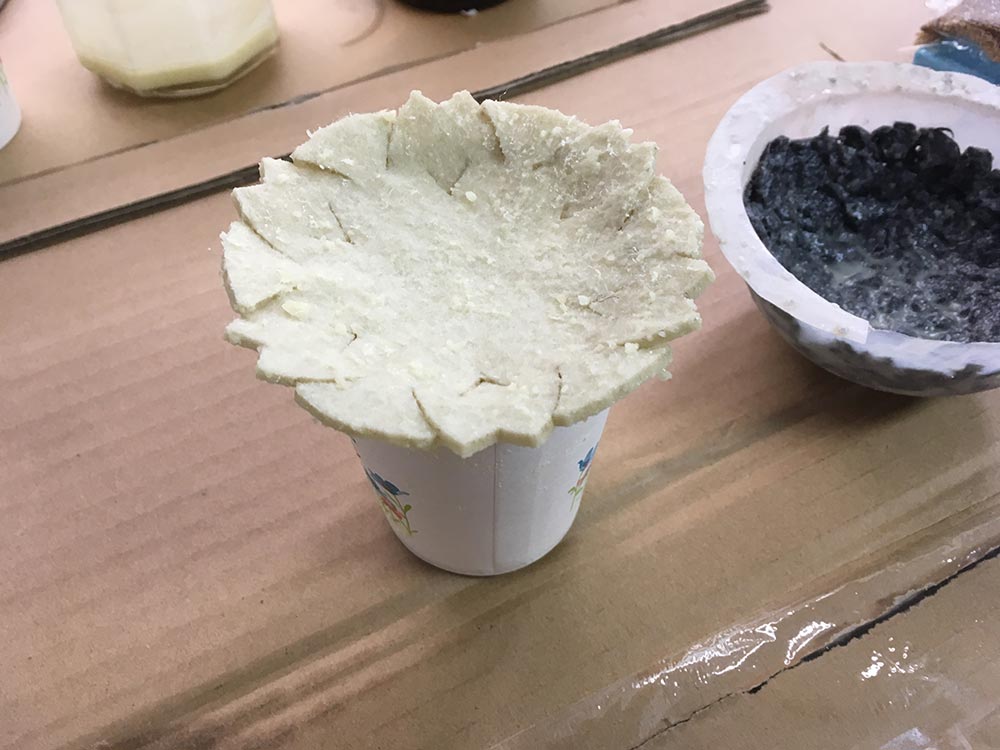

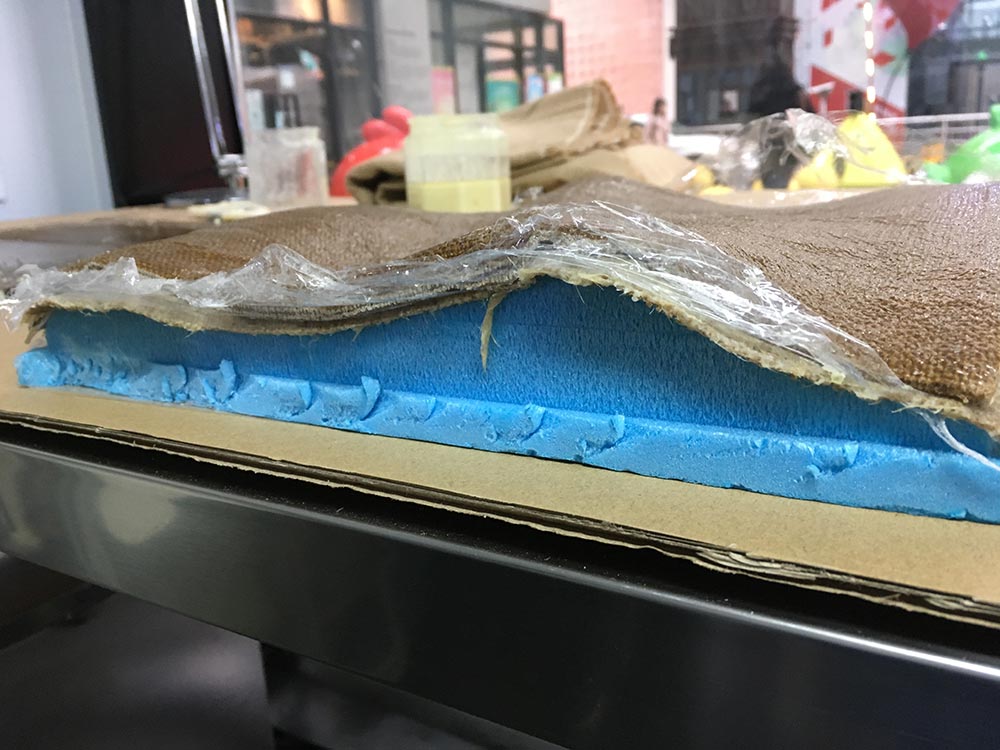

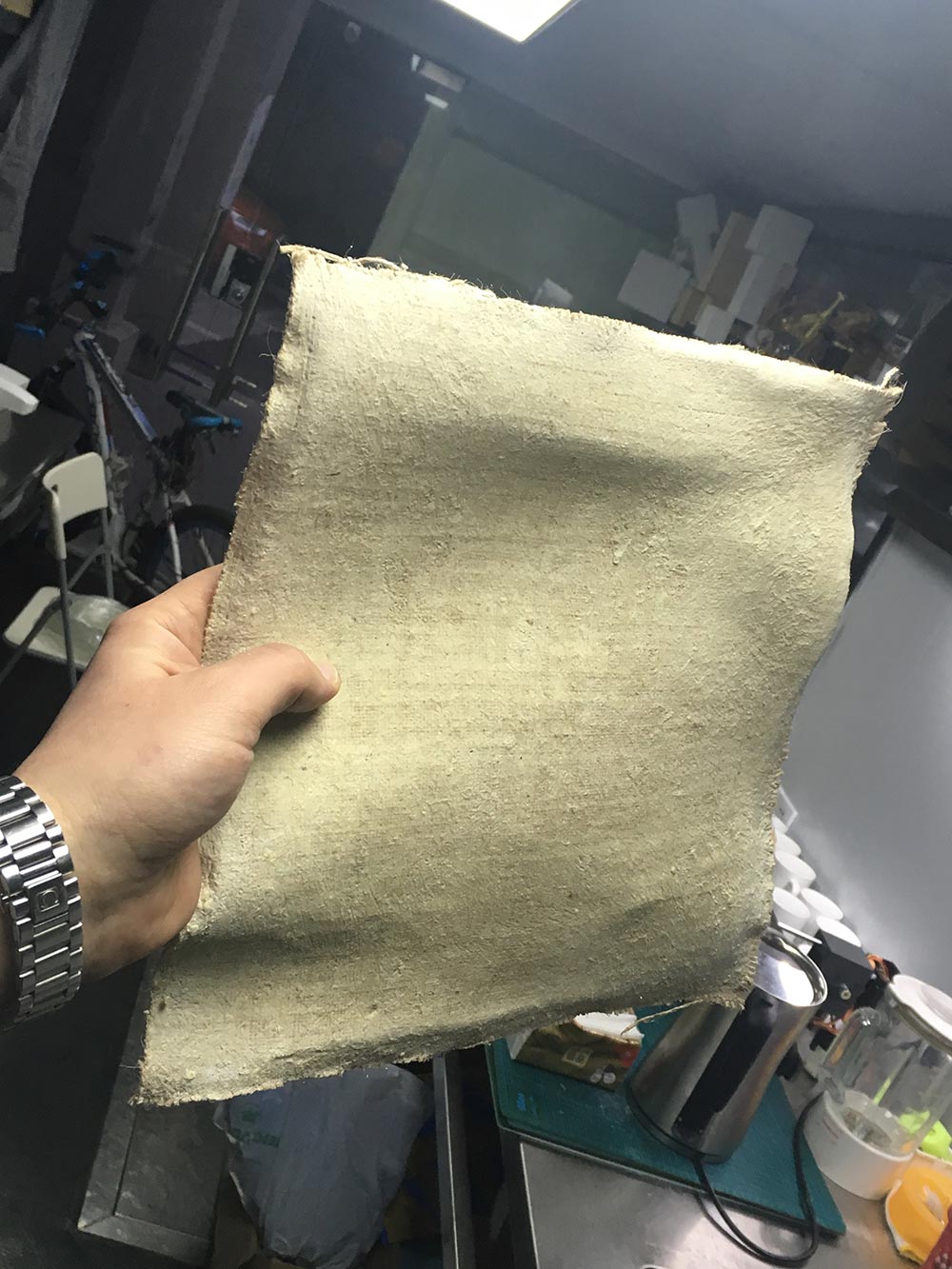

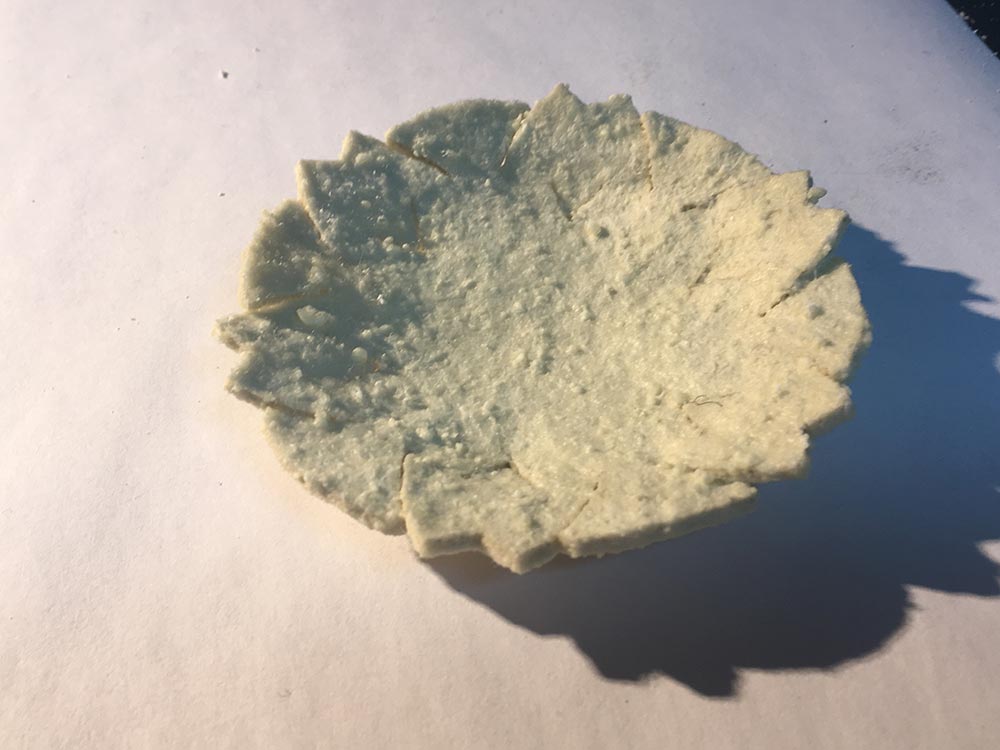

I was able to find 70% Alcool and Acetone and I used both separately to dilute the Colophonia. Acetone worked instantly, while Alcool didn't work well and it diluted maybe 10% of the colophonia over a 3 days time. Maybe it is not a good kind of alcohol. This week I only had time to make some tests and I tried diluted colophonia on the following materials:

The reason why I used the CNC styrene mold and the LDPE vacuum-thermoformed bold is because I intend to use one of this material/technique to make the scaffold mold. The LDPE is sourced from used 4lt water bottles

Results

It took a long time for anything treated with colophonia to dry up and loose the sticky feeling to the touch. When manipulated, heat from the hands makes the colophonia a little sticky again. The objects are very rigid and even the thin 30x30cm piece which is almost flat can stand straight without bending. The thicker pieces like the felt piece and the washingmachine filter stuff are very rigid. I think it is an interesting material, but it is way too messy to work with, has long drying time and cannot be manipulated, so it is maybe more suitable for objects that don't need interaction.

Experimenting with alum crystals

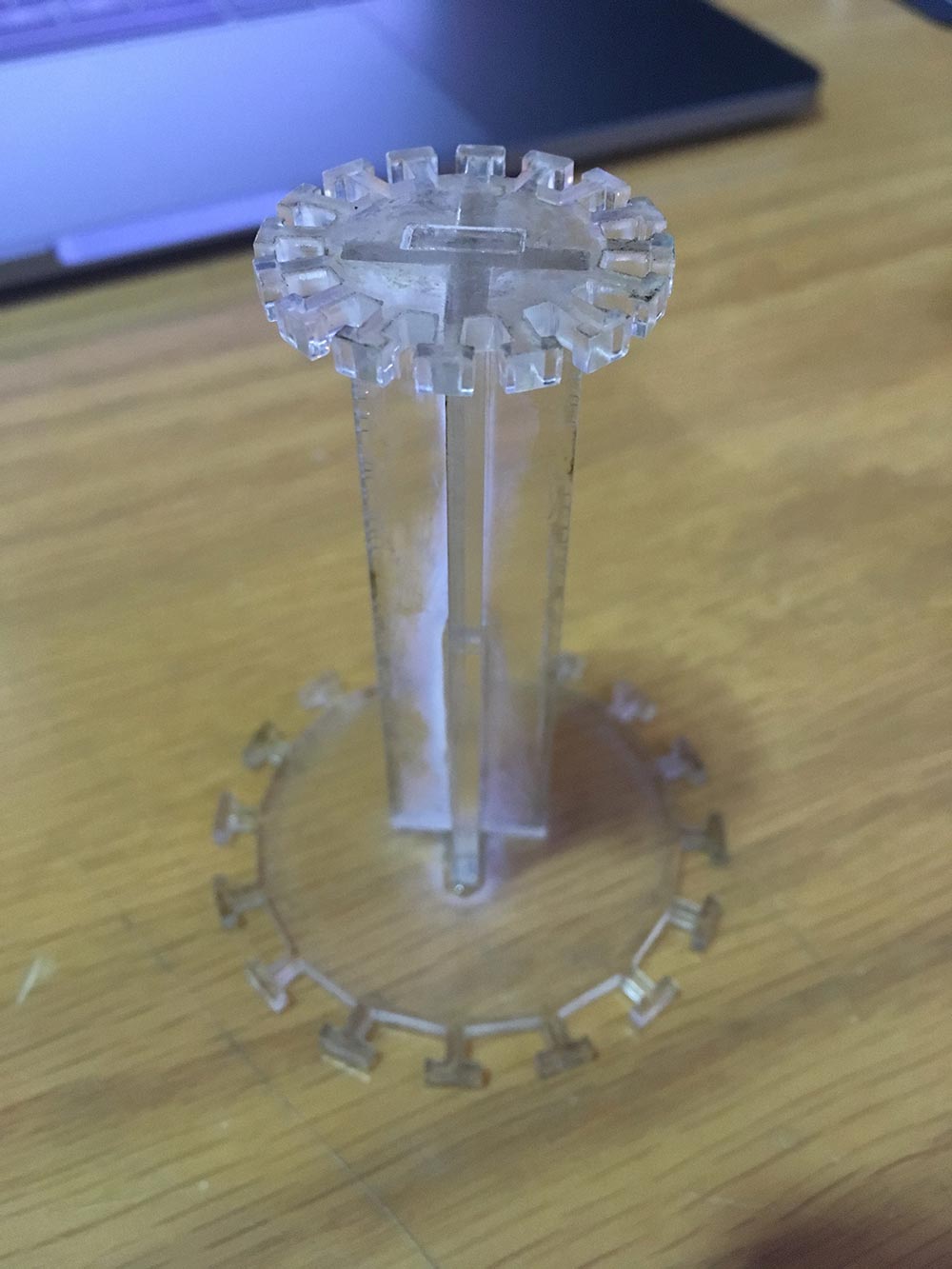

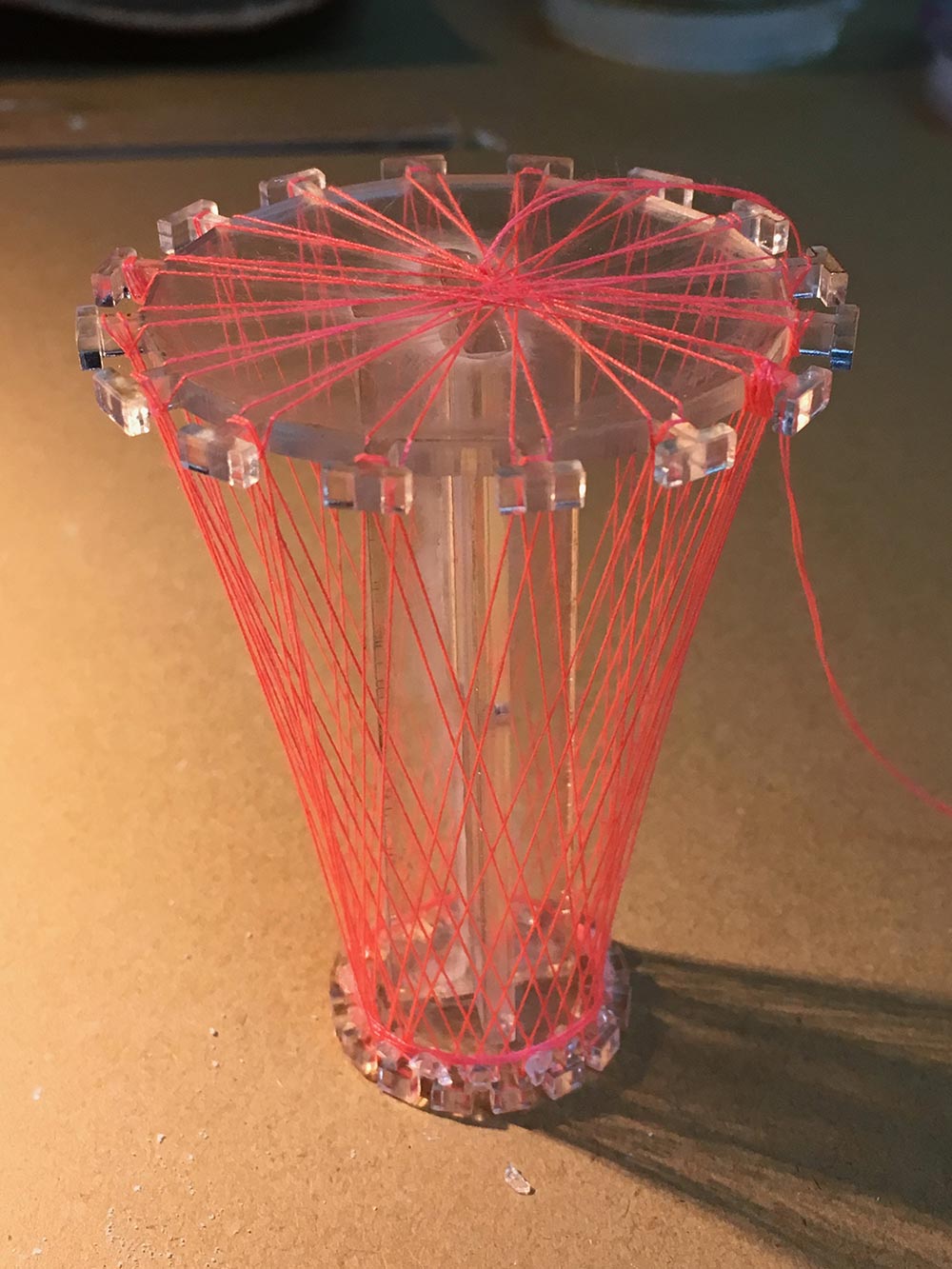

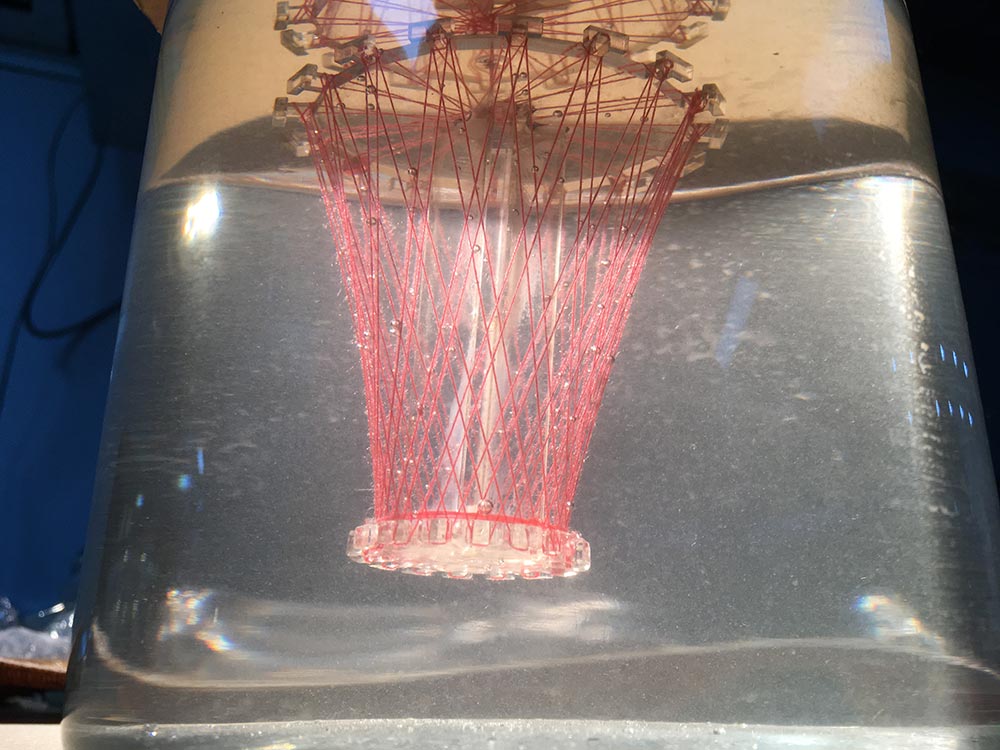

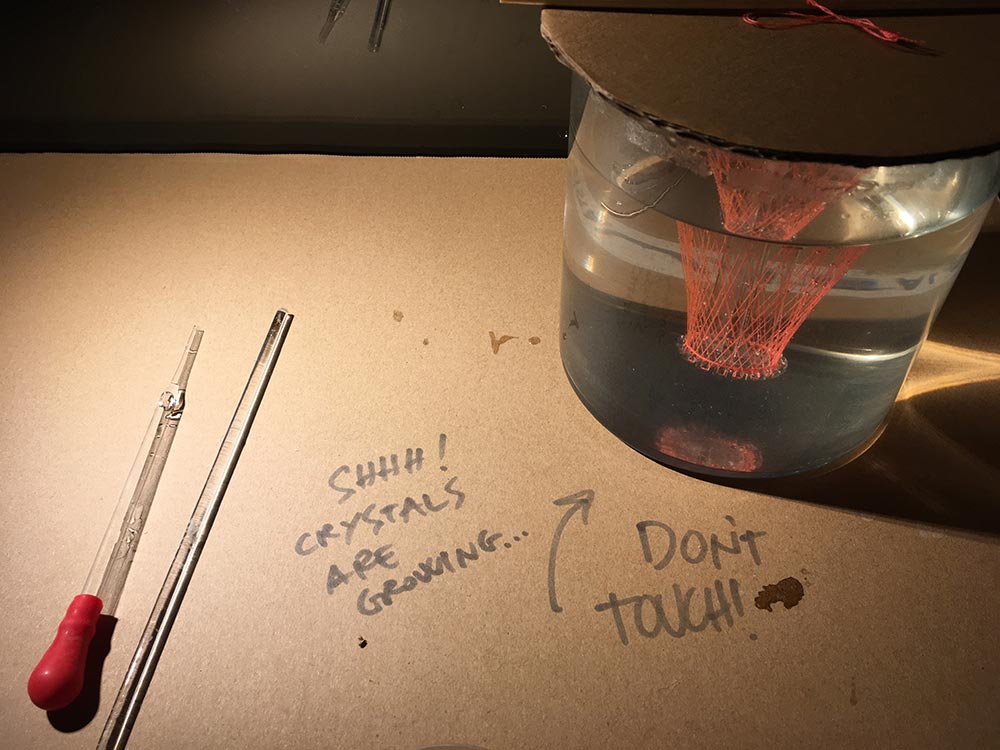

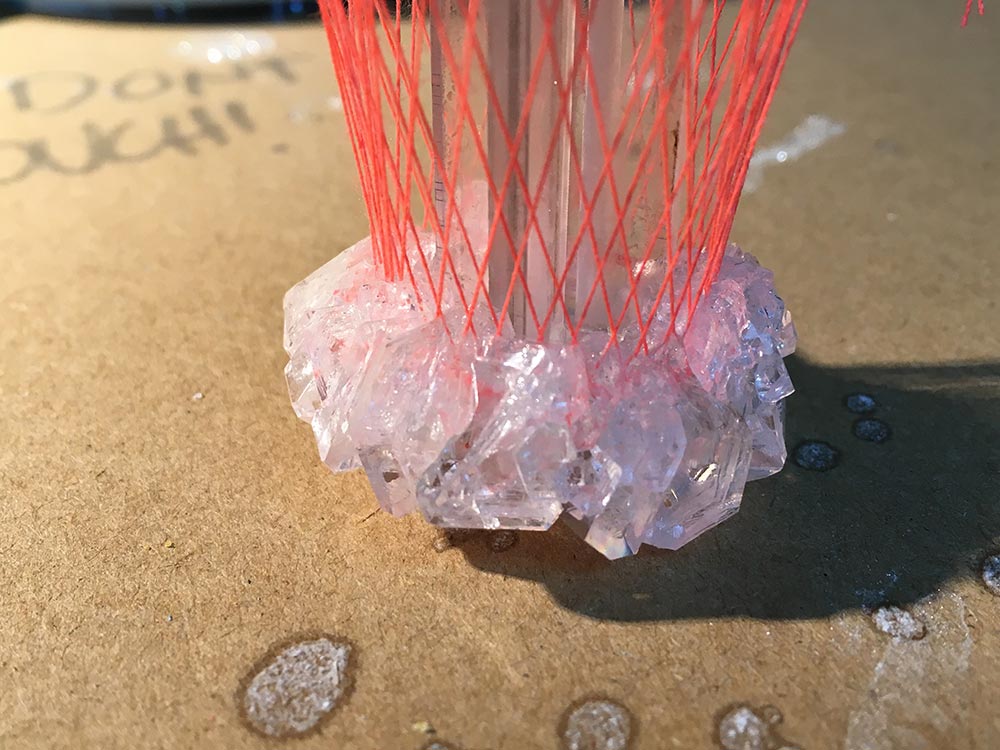

To make some experiment with crystal growing, I first made a solution of water and alum and let it grow for a night. Meanwhile I designed and lasercut an acrylic structure with two wheels that I connected with simple sewing thread. The day after I chose some of the nicest crystals from the solution and I insert them between the threads in the structure I mad, then I put all of it into a new solution of water and alum.

The next days the alum crystal started expanding and I took the structure off the water tank. Then I made a new solution and put it back in at a different angle: I discovered that while alum falls on the bottom of the tank, you get the biggest growing on the top surfaces of your object. After three times changing the water and moving the structure, I ended up with a glass-like shape. I cracked the acrilic disc on the top, while the bottom one rest encapsuleted inside the crystals.

Files Storage

This website by Saverio Silli (based on Twitter Bootstrap) and all its content is licensed under the following license: CC Attribution-Share Alike 4.0 International.