Biodyes & Biofabrics

Class four - 17 October 2017

Previous growing experiences

I was waiting for this week's assignment with great interest. In May 2017 at FABO we had the luck to host Camila Rios from Santiago for a short internship. During this period she conducted an experiment on growing Kombucha and I helped her sourcing the material and setting up the experiment. She produced a thick rectangular piece of Kombcuha that after drying became approximately 2mm thick. After she left the box containing the acid solution and the remaining Kombucha was left unattended in the hot Shanghainese summer for another month, until one day I was cleaning the lab and noiticed that a new layer of Kombucha grew in the box. So I collected it, washed with fresh water and let it dry on a piece of plywood as Camila taught me. It was just a couple of mm thick and after drying it became very thin like paper. It remained in the lab untouched until last week when I made some consideration and experiments: what amaze me is that it is really dry and yet very flexible and resistant. I left it in water for a day, thinking it would dissolve, but it was unaffected and once dried it went back to the previous condition. I'll try to make a new cultivation in the next month, trying to achieve again a very thin layer, as I plan to test it for using as packaging material.

Bio-dyes: purple sweet potato

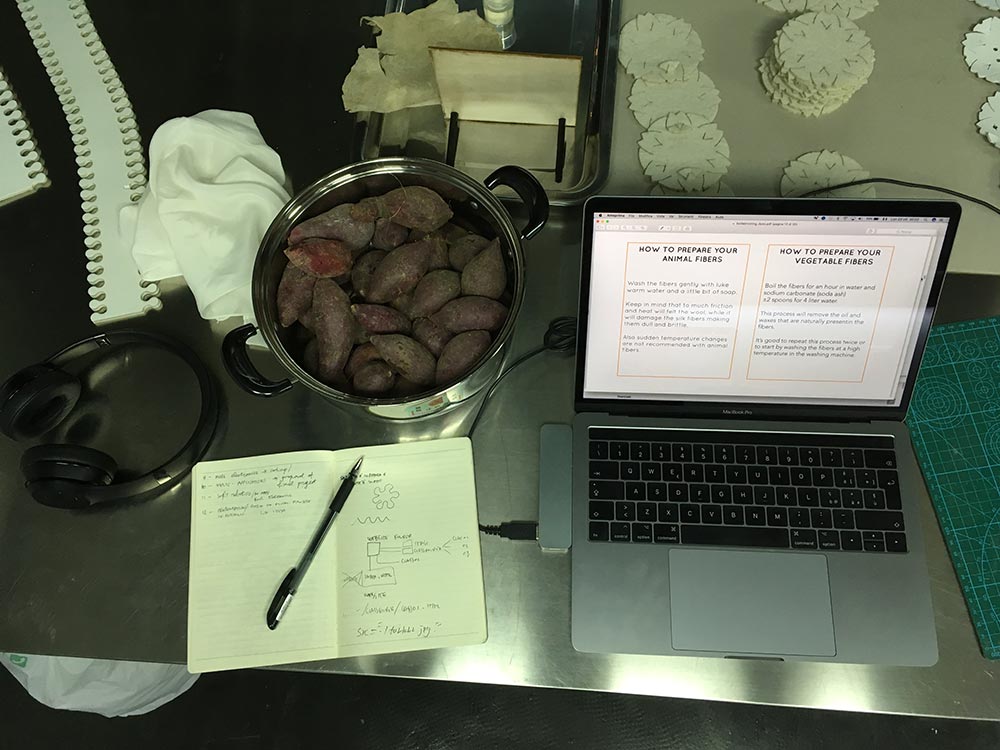

This autumn I had my first encounter with one of the most amazing food I have tasted and cooked: Purple Sweet Potatoes. Not only they taste and smell incredibly good, they also have the most amazing color I have seen in a kitchen. I knew I wanted to use this vegetable long before the Textile Academy even started.

| Material: | Dioscorea alata | |

|---|---|---|

| Pigment: | Anthocyanin | |

| Color: | pH < 7 | red, pink |

| pH ~ 7 | purple | |

| pH > 7 | greenish-yellow |

Acquiring the materials

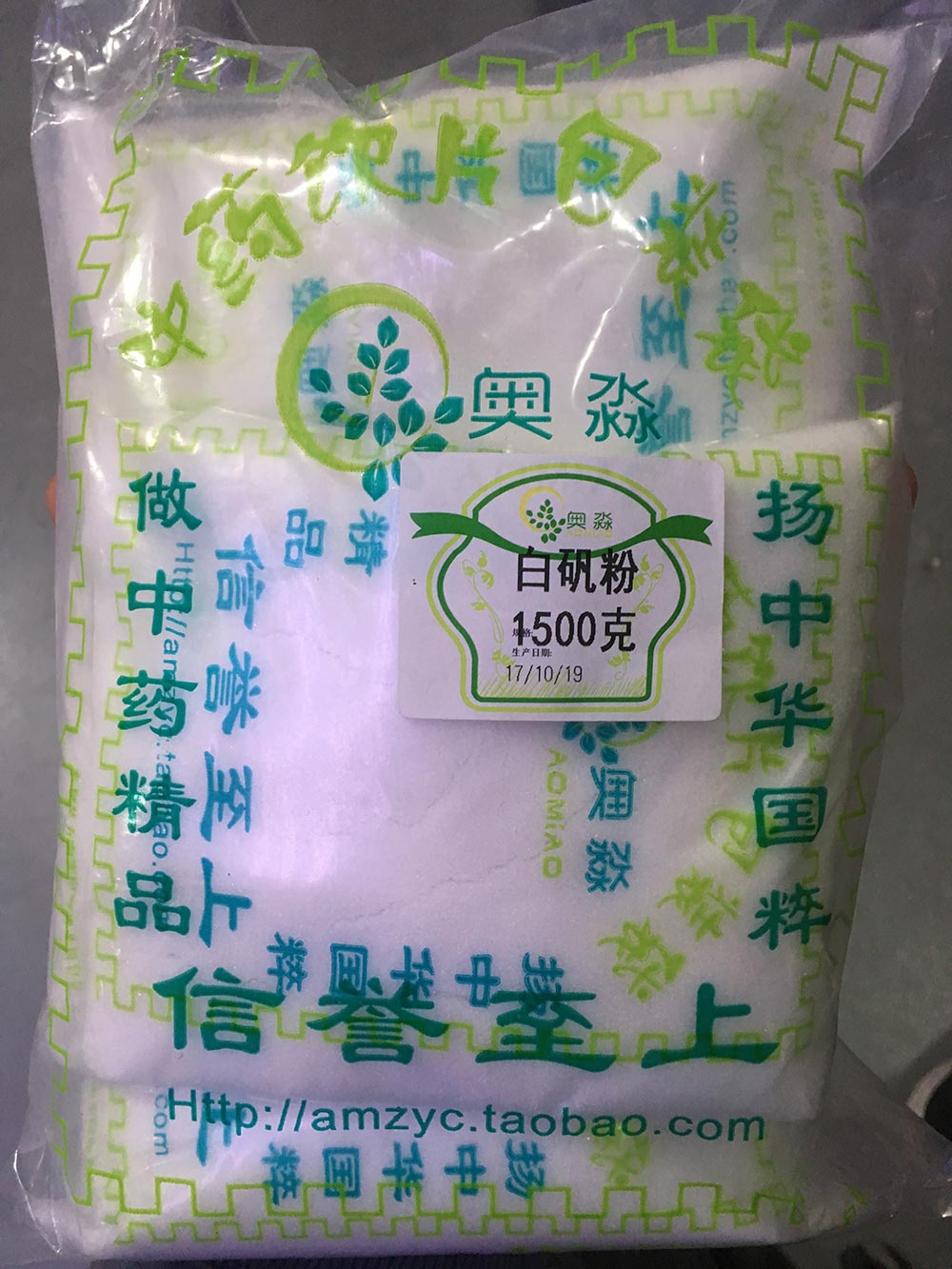

I wanted to try with both vegetable and animal fiber, so I started searching for "ingredients" on Taobao. Unfortunately I'm sourcing the material week by week as I am still learning and I always experience delays in the delivery and delays in my assignment. Any way, I was able to source all the material I wanted by Sunday and I am now in the process of experimenting, even if delayed. My documentation will keep growing over the next weeks. The list of my materials:

Extracting the dye

The first step is to extract the dye from the potatoes. I made two different batch, one using the skin and one using the peeled potato

| # | Material | Weight | Water | Cooking Time (<100°) |

|---|---|---|---|---|

| 1 | Peeled Potato | 400gr | 1000ml | 15min |

| 2 | Potato skin | 150gr | 500ml | 15ml |

First considerations

The peel contains a lot of dye as the color is more powerful compared to less water used to extract it. I made some preliminary experiment adding Vinegar to increase the acidity and Baking soda to reduce it. The shades go from acid green (which is actually basic!) to a very beautiful shades of pink and red. I kept one batch of pigment the original purple color and a second batch I made pink by adding vinegar and I used both to dye silk and cotton.

Mordanting the silk and cotton

To make the silk and the cotton ready to accept the dye, I put them into a pot with warm water and Alum (in two separated moments). After sitting in the pot for an hour I extracted the fabric and lay it on a tray without rinsing it. When I was ready to dye the fabric I added it directly into the warm pot with the pigment and left it there for a night.

Files Storage

This website by Saverio Silli (based on Twitter Bootstrap) and all its content is licensed under the following license: CC Attribution-Share Alike 4.0 International.